SEEFOR 13(1): 53-64

Article ID: 2205

DOI: https://doi.org/10.15177/seefor.22-05

ORIGINAL SCIENTIFIC PAPER

Physical and Fuel Properties of Bambusa vulgaris of Different Age Groups and Their Effect on Producing Biofuel

Kwaku Antwi1,*, George Adu2, Sylvia Adu3, Joseph Appiah-Yeboah4

(1) Akenten Appiah - Menka University of Skills Training and Entrepreneurial Development Faculty of Technical Education, Department of Construction and Wood Technology Education, P.O Box 1277, Kumasi, AAMUSTED Avenue 12, 00000 Tanoso-Kumasi, Ghana;

(2) Kumasi Technical University, Faculty of Built and Natural Environment, Department of Interior Design and Materials Technology, P. O. Box 854, Kumasi, Asafo Avenue 4, 00000 Asafo-Kumasi, Ashanti Region, Ghana;

(3) Kwame Nkrumah University of Science and Technology, Faculty of Renewable Natural Resources, Department of Forest Resources Technology, Mango Road, St 35 00000 KNUST-Kumasi, Ghana

(4) Mampong Technical College of Education, Department of Technical and Vocational Education, Box 31, MAMPTECH Avenue 56, 00000 Mampong – Ashanti, Ghana

Citation: Antwi K, Adu G, Adu S, Appiah-Yeboah J, 2022. Physical and Fuel Properties of Bambusa vulgaris of Different Age Groups and Their Effect on Producing Biofuel. South-east Eur for 13(1): 53-64. https://doi.org/10.15177/seefor.22-05.

Received: 28 Sept 2021; Revised: 9 Nov 2021; 13 May 2022; Accepted: 17 June 2022; Published online: 29 June 2022

Cited by: Crossref Google Scholar

Abstract

Bamboo can be used to produce solid, gaseous, and liquid fuels, as well as to generate heat and biofuels for transport and electricity. The main objective of this study was to investigate the physical and fuel properties of Bambusa vulgaris in three ecological zones for their utilization potential for the production of biofuels. Thirty-six samples of Bambusa vulgaris culms from 3 ecological zones in Ghana were milled to powder to assess the physical and fuel properties. The physical properties; moisture content, high heating values, bulk density, density, and ash content were investigated. The fuel properties were based on ultimate analysis, carbon, hydrogen nitrogen, and oxygen. The mean moisture content (MC) for the green bamboo ranged from 68.8% (dead culm) to 148% (mature culm) and 168% (juvenile culm). The MC for dried samples ranged from 9.09 to 13.06%. The results showed that the % MC of the samples increased with decreasing values of high heating and ash content. The mean density of the matured bamboo culms varied from 616.84 to 641.68 kg·m–3 and dead bamboo culms from 609.01 to 632.72 kg·m–3. Marginal reduction in density was observed in dead bamboo culms across the three ecological zones as compared to the mature bamboo culms. This implies that when B. vulgaris overgrows, its density decreases. High heating values ranged from 16.12 to 18.14 MJ·kg–1. Bulk density determines the transportation and storage of biomass; it ranged from 0.12 to 0.52 g·m–3. The ash contents were within the threshold (≥3%) of European standard. The mean values for the ultimate analysis of carbon (48.46 to 53.31%), hydrogen (5.60 to 6.56%), nitrogen (0.58 to 0.61%), and oxygen (39.73 to 41.35) were higher. Fuel properties of Bambusa vulgaris are comparable to some wood types, lower to denser wood types, but higher than most of the herbaceous energy crops and agricultural residues. This means that Bambusa vulgaris may be a good feedstock for the production of bioenergy in terms of heat, charcoal, biogas, bio-power, and transportation fuel.

Keywords: Bamboo; biomass; biofuel; high heating value

INTRODUCTION

The world demand for petroleum-based fuels has increased as a result of increasing industrialization and motorization (Agarwal 2007). Resources like gasoline, coal, natural gas, diesel and other products derived from fossil fuels are non-renewable (Brown 2003) because they cannot be regenerated once used. Many researchers reported that the burning of fossil fuels emits extensive greenhouse gases, such as carbon dioxide, into the atmosphere, which are the sources of some other severe environmental problems (Davis and Caldeira 2010, Street and Yu 2011). The intensive use of fossil fuels and other natural resources accumulate greenhouse gases which cause heat over the Earth’s surface, resulting in changes in temperature and other climatic processes (Koutsoyiannis et al. 2009). These emissions among others have brought about climate change such as global warming, flooding (World Bank 2009), droughts, famines, water shortages, extreme heat (Koutsoyiannis et al. 2009, Riché et al. 2009), and desertification (World Bank 2009).

Global wood charcoal production rose from 17.3 to 53.1 million tons between 1964 and 2014. Sixty-one percent of the present global production of charcoal occurs in Africa to satisfy the cooking demand from urban households (Doggart and Meshack 2017). World Health Organization (WHO) revealed that over 75 percent of rural households and around 20 percent of urban households depend primarily on wood fuel for cooking in low- and medium-income countries (WHO 2016). A shift from fossil fuel-based energies to dependence on renewable energy had been discussed by many researchers (Demirbas and Arin 2002, Prins 2005, White 2010). Several researchers have proposed the use of these renewable energies as substitutes for fossil fuels; solar, wind, hydro, ocean thermal energy, and biomass. Among the renewable energy sources mentioned above, biomass is the only carbon-based sustainable energy (Sathre and O’Connor 2010). Biomass can be burned to produce heat and electricity; changed to gas-like fuels such as methane, hydrogen, and carbon monoxide, or changed to liquid fuel. Liquid fuels, also called biofuels, include mainly two forms of alcohol: ethanol and methanol (Demirbas 2010).

Wood and energy crops were the main biomass substrate for the production of biofuels (Demirbas and Arin 2002, Filho and Badr 2004), agricultural and forestry residues, animal wastes, (Demirbas and Arin 2002, Bridgwater 2004) municipal solid wastes, manufacturing wastes, and vegetable oils (Filho and Badr 2004). Trees and crops can always be grown and waste will always exist (The NEED Project 2011). By nature, biomass materials vary depending on geographical location, variety, climate conditions, and harvest methods (Clarke and Preto 2011). The demand for biofuel was insatiable; as a result, many researchers around the world have delved into using lignocellulose materials such as wood, crops, and agricultural wastes to produce biofuels (IEA 2010). Between 2000 and 2010, global biofuel production grew from 16 billion liters to 100 billion liters (IEA 2011). However, frequent use of woody biomass for bioenergy (electricity, gas, or heat) production is expected to have some ripple effects in the forest and agriculture sectors. Increased use of the mill and forest residues for bioenergy will likely decrease the production of oriented strand boards, bark mulch recycles soil nutrients, and improve micro-climate site conditions (White 2010). Countries like Brazil, Canada, and the USA are using sugar cane, wheat, corn, or soya respectively to produce bioethanol (Koh and Wilcove 2008). Food crops used for biofuels have adverse effects on the food supply to humans, poultry, and farm animals and increase food prices (Sun and Cheng 2002). Bamboo was seen by many researchers as the most promising energy source to mitigate greenhouse gas emissions (Demirbas 2010, Preto 2010). Bamboo has a very wide variety of energy needs, including generating electricity (Demirbas 2010, Preto 2010), high heating homes (Preto 2010), fuelling vehicles (Bain 2010), and providing process heat for industrial facilities (Preto 2010). Bamboo is a sustainable, fast-growing plant that takes 3 to 4 years to mature (INBAR and BARADEP 2003). Bambusa vulgaris is the most common type of bamboo, which covers about 95% of the total growing area in the southern part of Ghana (Oteng-Amoako et al. 2005).

The knowledge of utilizing bamboo for the production of biofuels is increasing, but most of the studies dealt with only studied mature culms (Choy et al. 2005), neglecting the potency of the shoot, young and dead culms, branches, and leaves. Scurlock et al. (2000) studied nine bamboo ages from 1 to 5 years, i.e. juvenile and mature culms. However, they did not consider ecological zones, shoots, over-grown or dead culms for fuel properties. Again, little is known about the characteristics of bamboo as a feedstock for the production of biofuel in West Africa. This study aims to determine the physical and fuel properties of Bambusa vulgaris Schrader ex Wend land var. vulgaris (Bamboo) age groups: shoots, juvenile, mature, dead, or overgrown. The tested hypothesis of the study is to determine the physical and fuel properties such as density, bulk density, and high heating value of Bambusa vulgaris age group culms. The results imply utilizing these bamboo parts for energy production.

MATERIALS AND METHODS

The Study Areas

The samples of bamboo were collected in their natural stands from three ecological zones in Ghana. These areas were dry semi-deciduous zone (DSD), moist semi-deciduous (MSD), and moist evergreen deciduous (MED). The DSD zone is located in the transitional zone between Ghana’s forest and Savanna regions (FAO 2005). The area covered a forest near Techiman in the Brong East Region of Ghana, which is between 7°35' N latitude and 1°48' W longitude. The mean annual rainfall ranges from 1300 to 1400 mm (Obiri and Oteng-Amoako 2007). The highest annual temperature is 33°C (Duku et al. 2011). The next area of study was Owabi forest reserve, near Kumasi, which is positioned between 6°46' N latitude and 2°3' W longitude in Ashanti Region. The forest is located in the moist semi-deciduous (MSD) forest zone (Hall and Swaine 1981). The average annual rainfall ranges from 1400 to 1750 mm (Obiri and Oteng-Amoako 2007) and the highest annual temperature is 31°C (Duku et al. 2011). The last investigated area was Bonsa River Forest Reserve in the moist evergreen – deciduous (MED) zone. The reserve is located between the coordinates of 5°15' latitude and 2°45' W longitude in the Western region of Ghana. The mean annual rainfall ranges from 1700 to 2800 mm (Obiri and Oteng-Amoako 2007).

Preparation of the Samples

Four age groups of Bambusa vulgaris, shoot, juvenile, mature and dead culms, were used for the experiment. The juvenile, mature and dead bamboos were measured at 300 mm intervals each. Mature branches (green and dry) and leaves (green and dry) were characterized in terms of moisture content, basic density, ultimate composition, high heating values, and ash content. The samples were oven-dried at 103±2°C and pulverized to fine powder by using a Wiley mill (Scurlock et al. 2000, Templeton et al. 2009). The milled samples were mixed toughly to obtain homogenization in a sieve shaker to pass through a 425 µm mesh sieve but retained on a 250 µm mesh sieve. The powder obtained was oven-dried again for the fuel analysis.

Determining the Moisture Content

Two grams of each powdered sample were weighed on an analytical balance and placed in different crucibles. The crucibles were then labelled and placed in the oven which was kept at a temperature of 105˚C. Each crucible and sample were taken out of the oven regularly and weighed. Gradual decreases in weight were observed and the drying and weighing continued until there was no observed change in the weights after several weighing. The calculation is as follows:

% Moisture Content (MC) = (M - Mo/ Mo) × 100 (1)

where M is the mass of the test piece before drying, and Mo is the mass of the test piece after drying.

Determining Bulk Density Measurement

Bulk density is also called volumetric or apparent density. This is where the properties of powders, granules, and other divided solids are compacted or tapped in volume. Bulk density increases with compaction and tends to increase with depth. The measurement of bulk density was based on ASTM E873 (2013).

The powdered bamboo sample was sieved to a 60-mesh screen (250 microns). The fresh sample was weighed (W1, dry at 105oC for 2 days), and weighed again (W2). The calculation is as follows:

Bulk density = W2/V (g ·cm–3) (2)

Water content (Theta) = (W1 – W2)/V (cm3·cm–3) (3)

Determining Dry Density

The density of solid bamboo was determined by using ISO 3131 (1975) standard. The dry density is the ratio of the density of a test specimen to its volume. The density was used to report the natural moisture content of the test specimen. Here the mass is taken as the oven-dried mass and only the volume is taken at the natural moisture content of the specimen. The density of each test sample is calculated by using Equation 4:

D = m/v (106) (4)

where D is density in kg·m–3, m is the oven-dried mass in grams of the test specimens, and V is the oven-dried volume of the test specimens in mm3.

Determining High Heating Value (HHV)

The powdered bamboo sample was pelleted and oven-dried to constant weight at 80°C. It was then burned in an oxygen bomb calorimeter calibrated by burning benzoic acid in the same way as the sample (Technical Support Document 2007). The calculations were as follows:

Heat capacity of the system

Ccal = Q / ΔT· c (5)

where Ccal is heat capacity of the calorimeter, Q is heat capacity of the object, ΔT is change in temperature and c is specific heat capacity;

Q = m/ΔH (6)

where ΔH is molar combustion enthalpy of benzoic acid = − 3231.5 kJ/mol and m is molar mass of Benzoic acid.

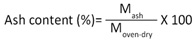

Determining the Percentage (%) Weight of Ash Content in the Bamboo Age Groups

The ash content of the bamboo was determined by ASTM D 1102 (2008). Two grams of the powdered bamboo sample were oven-dried in an electric furnace at a temperature of 600˚C for four hours. The percentage of the ash content was calculated as follows:

(7)

(7)

where Mash is the mass of the ash and Moven-dry is the mass of the oven-dried sample.

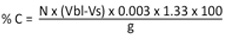

Determining the Percentage (%) Weight of Carbon

Carbon in the bamboo was determined by using Walkley – black wet oxidation method (Nelson and Sommers 1982). The percentage of carbon (C) was calculated as:

(8)

(8)

where N is Normality of ferrous sulphate = 0.5 N, Vbl is liter value of the blank solution, Vs is liter value of sample solution, g is mass of sample taken, 0.003 is milliliter equivalent weight of C in grams (12/4000), 1.33 is correction factor used to convert the wet combustion C value to true C value since the wet combustion method is about 75% efficient in estimating the C value (100/75).

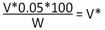

Determining the Percentage (%) Weight of Hydrogen

The hydrogen content was determined using the exchangeable acidity titrimetric method (Mclean 1965). The following calculation was used:

(9)

(9)

where V is titre volume of NaOH used (ml); normality of NaOH = 0.05N and W is weight of sample used (1.0 g).

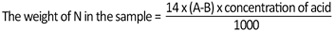

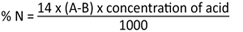

The Percentage (%) of Nitrogen

The Kjeldahl method was used to determine nitrogen in chemical substances (Motsara and Roy 2008). The weight of N was calculated as: 14 g of contained in one mile-equivalent weight of NH3:

(10)

(10)

where A is volume of standard HCl used in the sample titration and B is volume of standard Cl used in the blank titration.

The percentage of nitrogen in the sample is calculated as:

(11)

(11)

Determining Nitrogen (Kjeldahl Method)

One gram of the shell/nib was weighed and transferred into a 500 ml digestion flask and 30 ml of H2SO4 was added. The digestion flask with the mixture was heated in the DK20 high heating digester block starting at a temperature of 80oC and then the temperature was raised to 350oC. The content of the digestion flasks was heated until the volume was reduced to 3 to 4 ml. The content of the digestion flasks was cooled and the volume made up to 100 ml in volumetric flasks. The volumetric flasks were labelled accordingly. Ten millilitres of sample digest were transferred using a pipette into a Kjeldahl distillation apparatus after the addition of 20 ml of 40% NaOH. The distillate was collected over 10 ml of 4% boric acid and three drops of mixed indicator in a 250 ml conical flask for 5 minutes.

The presence of nitrogen gave a light blue colour. 200 ml of the distillate was titrated with 0.1 N HCl till the colour changed from light blue to grey and suddenly flashed to pink. A blank was carried out with the solution sample. The weight of N was calculated as 14 g of N contained in one mile-equivalent weight of NH3.

RESULTS

Moisture Content

In green conditions, the moisture content of Bambusa vulgaris varies with the age and height of the culm and the geographical location of the bamboo (Figure 1). The moisture content decreases from the shoot to the over-grown (dead) culm and also from the bottom or base of the culm to the top in all three ecological zones. Among the bamboo culms sampled from the three ecological zones, those from the moist evergreen ecological zone had the highest average moisture content of 157% (juvenile), 148% (mature), and 68.8% (dead).

One-way ANOVA test showed that at 5% level of significance the average moisture content of the shoot (F-statistic=11.04, p-value=0.010), juvenile culms (F-statistic=5.58, p-value=0.043), mature culms (F-statistic=22.03, p-value=0.002) and over-mature culms (F-statistic=48.62, p-value=0.001) sampled from the three ecological zones differed significantly. The coefficient of variation of the shoot culms, juvenile culms, mature culms, and the over-mature culms were 5%, 6%, 10%, and 11% respectively.

The Percentage Dry Moisture Content of Bambusa vulgaris Across the Three Ecological Zones

The mean moisture content of the dry bamboo samples increased from dry semi-deciduous zone to moist evergreen deciduous zone among the age groups. Table 10 shows the moisture content (dry bamboo); the shoots ranged from 9.09% to 9.19%, juvenile scored 13.24% to 13.31%, mature culm obtained 12.93% to 13.06% and dead culm recorded 11.02% to 11.06%. It could be observed from Table 1 that there were statistically significant differences among the shoot, matured and the dead culm mean diameters for all the ecological zones. The test for juvenile shows positive results for shoot (p-value=0.055, juvenile (p-value˂0.000), matured (p=0.002) and dead samples (p-value˂0.000).

The Density of Bambusa vulgaris Across the Three Ecological Zones

Mature culms of the green Bambusa vulgaris have marginal increases in the density of the samples from the three ecological zones, ranging from 616.84 kg·m–3 (DSD) to 628.12 kg·m–3 (MSD), and 641.68 kg·m–3 (MED). A marginal decrease in density was observed for dead bamboos across the three ecological zones (Table 2). The mean values for the dead culm range from 609.01 kg·m–3 (DSD) to 620.21 kg·m–3 (MSD) and 635.72 kg·m–3 (MED).

Bulk Density of the Bambusa vulgaris Across the Three Ecological Zones

The mean bulk density exhibited a more definite pattern of variation within and between all the zones (Table 3). The mean values increased from dry semi-deciduous, moist semi-deciduous to the moist evergreen zone. The mean bulk density of shoot ranged from 0.13 to 0.17 g·m–3, juvenile from 0.17 to 0.28 g·m–3, mature ranged from 0.28 to 0.32 g·m–3 and dead recorded 0.32 to 0.52 g·m–3. On the whole, the samples from moist evergreen recorded the highest values. On the contrary, the samples from dry semi-deciduous got the lowest values. The mean values of the juvenile and dead culms were statistically significant.

The High Heating Values of the Bambusa vulgaris Across the Three Ecological Zones

The average high heating value ranged from 16.12 to 18.14 MJ·kg–1. The results showed a consistent rise of values from MED upstream to MSD in the middle belt, then to DSD transitional zone between the forest and savanna regions. It could be observed from Table 4 that the highest average high heating value amongst the culms of the three zones was recorded at the dead culms (18.14 MJ·kg–1) from dry semi-deciduous (DSD).

Means in the row with different letters indicate a significant difference at the 5 percent probability. Significant differences were found in the mature and dead bamboo culms sampled from the three zones in respect to high heating values. Culms sampled from both the dry semi-deciduous and moist evergreen had significantly higher high heating values than those from the moist semi-deciduous zone.

The Percentage (%) of Ash Content of the Bambusa vulgaris Samples

The values of the mean ash contents across the three ecological zones are presented in Table 5. The shoot exhibited values ranging from 1.51% (moist evergreen) to 1.72% (moist semi-deciduous zone). The average weight of ash in the juvenile samples was from 1.71% (moist evergreen) to 2.01% (moist semi-deciduous zone). The mature samples ranged from 0.93% (moist evergreen) to 1.83% (dry semi-deciduous zone). The values of the dead bamboo samples recorded were as follows: the lowest average value recorded in the moist semi-deciduous zone was 1.15% and the highest was 2.17% located in the moist evergreen zone.

Significant differences were found for the shoot (F=7.892, p=0.021) and the mature (F=2.318, p= 0.002) sampled from the three zones in respect of ash content.

Percentage (%) Weight of Carbon Concentrations in Bambusa vulgaris Across the Three Zones

The mean highest carbon values rose from the dry semi-deciduous to the moist evergreen zone. The mean shoot varied a little from 49.74% in moist evergreen, 49.67% in moist semi-deciduous, and 48.46% in dry semi-deciduous zone (Table 6). The percentages of the juvenile culms were generally higher at moist evergreen (53.31%), dry semi-deciduous recorded 50.10%, while moist semi-deciduous zone had 52.24%. The mature culms obtained the following values: 48.58% in the dry semi-deciduous region, 50.84% in moist evergreen, and 52.82% in the moist semi-deciduous zone. Meanwhile, the dead bamboo culms have the following values: 52.14% for dry semi-deciduous, 52.75% for moist semi-deciduous, and 53.01% for moist evergreen zone.

Table 6 shows the one-way ANOVA test for the mean carbon content of Bambusa vulgaris in three ecological zones. Only the mature (F=5.993, p=0.037) and the dead (F=9.253, p=0.015) culms were statistically significant.

Percentage (%) Weight of Hydrogen Content in Bambusa vulgaris Across the Three Ecological Zones

From the results in Table 7, shoot recorded the mean values of 6.27% (dry semi-deciduous zone) to 7.04% (moist evergreen zone). The mean percentage weight of hydrogen in juvenile samples decreases marginally from dry semi-deciduous (6.17%) to moist evergreen zone (6.13%). The lowest mean percentage of hydrogen (6.34%) was recorded in the dry semi-deciduous zone and the moist semi-deciduous zone recorded the highest value of 6.56%. Meanwhile, the average hydrogen weight of dead bamboo samples ranged from 5.60% in dry semi-deciduous to 6.22% in the moist evergreen zone. The hydrogen level rose from a dry semi-deciduous to a moist evergreen zone. The highest value was recorded at the shoot (7.04%) from moist evergreen and the lowest was found in the dead (5.60%) located in a dry semi-deciduous zone.

Table 7 shows a one-way ANOVA test for the mean percentage hydrogen content in Bambusa vulgaris across three zones in Ghana. Only the shoot was statistically significant (F=15.571). Nonetheless, there were no significant differences among the groups.

Percentage (%) Weight of Nitrogen Concentrations in Bambusa vulgaris Across the Three Ecological Zones

The shoot from the moist evergreen zone recorded the lowest mean nitrogen content at (0.65%) and the highest at 2.52% in the dry semi-deciduous zone (Table 8). Juvenile samples from moist semi-deciduous recorded the lowest value of nitrogen of 0.61% and dry semi-deciduous recorded 0.79%. The nitrogen concentration in juveniles was higher than that of the rest of the culms. The percentage weight of nitrogen for mature bamboo varies from 0.58% (moist evergreen) to 0.61% (dry semi-deciduous), and the dead samples ranged from 0.32% (moist semi-deciduous) to 0.58% (moist evergreen).

There were significant effects of the amount of nitrogen on shoots (F=17.577, p˂0.05) and the dead culm (F=9.056, p˂0.05) of the bamboo.

The Mean Percentage Weight of Oxygen by Calculation

The mean percentage value of oxygen and standard deviation of the shoot was 40.20±2.45, the juvenile was 39.43±1.79, mature was 41.04±2.43 and dead culm was 41.35±4.05.

Fuel Characteristics of Bambusa vulgaris Across the Three Ecological Zones

The fuel characteristics of Bambusa vulgaris in terms of ultimate analysis, basic density, moisture content, and high heating values were investigated (Table 9).

![]() Table 9. Fuel characteristics of Bambusa vulgaris.

Table 9. Fuel characteristics of Bambusa vulgaris.

The mature culms exhibited the highest fuel yield, followed by dead culms in all the zones. The yardstick was based on positive attributes such as large carbon, hydrogen, high heating value, and high basic density. These were followed by the relatively low amount of moisture content, oxygen, nitrogen, and ash content which seem to decrease the fuel content in a substrate. The third and the fourth age groups were shoots and juvenile culms all based on the positive and negative attributes of fuel properties.

Relationships Among the Fuel Properties of Bambusa vulgaris Culms or Stems

Combustion analysis is part of a process intended to improve fuel economy, reduce undesirable exhaust emissions and improve the safety of fuel-burning equipment (TSI Incorporated 2004). The negative effects of some fuel properties will depend on the simultaneous presence of others. For example, the higher the moisture contents of fuel, the lower the high heating values (Montano 2014).

Table 10 shows that the correlation between the high heating value and hydrogen was very strong and positive (r=0.755). The relationship between high heating value and carbon was significant (r=0.724 and p=0.05). There was an intermediate negative correlation between the high heating value and the ash content (r=-0.603; p>0.05). There was a negative correlation between ash content and the carbon content (r=-0.872; p>0.05).

![]() Table 10. Pearson’s correlation test (p

Table 10. Pearson’s correlation test (p

The relationship between moisture content of wet and dried bamboo have strong positive correlation (r=0.727; p>0.05). There was a positive relationship between moisture content (dry basis) and the high heating value (r=0.059 and p>0.05). However, % moisture content of the wet bamboo is negatively related to high heating value (r=-0.188; p 0.05). There was negative correlation between moisture content (wet) and the ash content (r=-0.064 and p>0.05), whilst the dry bamboo is positively related to ash content (r=0.289 and p>0.05). Nitrogen is negatively related to basic density (r=-0.604 and p=0.05). There was a positive correlation between moisture content (wet bamboo) and basic density (r=0.145 and p>0.05).

DISCUSSIONS

Moisture Content in Bambusa vulgaris Across the Three Ecological Zones in Ghana

Moisture content varies from the bottom to the top of the fresh bamboo samples. The moisture content from the moist evergreen forest exhibited higher values than those from moist semi-deciduous and dry semi-deciduous zones in Ghana. The average moisture content of the fresh bamboo ranges from 52.43 (dead or over-mature) to 168% of the bamboo culms.

The higher the moisture contents of bamboo samples, the lower the high heating values. Efficiency is reduced because large parts of the energy available in the bamboo itself were used to heat up and evaporate this moisture. One way to increase efficiency would be to dry the fuel on-site. Higher moisture content increases both the cost of production and transportation of biofuel feedstock. High heating bamboos with more moisture content produce more smoke, which contains more volatile materials. The volatiles consist of minor and heavy metals such as arsenic, lead and sulphur, which are injurious to human health. The more moisture in the bamboo the less ash is produced. Probably most of the minerals and fixed carbon in the bamboo were evaporated in the form of smoke and steam. On the contrary, the lower the moisture content is, the more ash is produced. However, dense dried bamboo produces more low ash content than less dense bamboo.

Bulk Density of Bambusa vulgaris Across the Three Ecological Zones

The bulk density is in line with the research conducted by earlier researchers (0.13 to 0.52 kg·m–3) on bamboo and some seasoned or dried wood such as: Alder 0.4 to 0.7; Afromosia 0.71; Agba 0.65; Apple 0.65 to 0.85; Ash, white 0.54; Ash, black 0.54; Ash, European 0.71; Bamboo 0.30 to 0.40; Mahogany, Africa 0.50 to 0.85; Teak, Africa, 0.98; Utile 0.66; Walnut 0.65 to 0.7 (Engineers’ Toolbox n.d). Qisheng et al. (2002) also reported bulk density values from 0.40 to 0.90 kg·m–3 of Phyllostachys pubescence.

The Density of Bambusa vulgaris Across the Ecological Zones

The mean density of matured Bambusa vulgaris samples ranged from 616.84 kg·m–3 (DSD), to 628.12 kg·m–3 (MSD), and 641.68 kg·m–3 (MED). The results were in line with the results recorded by former authors in Ghana. For example, the basic density values ranging from 371.35 kg·m–3 to 684.00 kg·m–3 were reported by Tekpetey (2011). Ebanyenle and Oteng-Amoako (2007) recorded the basic density of Bambusa vulgaris in Ghana as 577.00 kg·m–3 in wet evergreen forest type and 684.00 kg·m–3 in moist semi-deciduous forest type. The data were collected in the rainy season.

The High Heating Values of Bambusa vulgaris Across the Three Ecological Zones

The average high heating values for the three zones were 16.12 MJ·kg–1 (juvenile) to 18.14 MJ·kg–1 (dead culm). It could be observed that the high heating value at the shoot and juvenile ages of bamboo in the net high heating value of bamboo is comparable to or higher than other wood species like the beach, spruce, eucalyptus, and poplars, which range from 16.02 to 18.25 MJ·kg–1 (Amoah and Cremer 2017).

Bamboo has low ash content, low alkali index, and lower high heating value. However, the high heating values of bamboo are higher than most agricultural residues, grasses, and straws. Meanwhile, it is lower than many woody biomasses (Scurlock et al. 2000).

The Ash Content in Bambusa vulgaris Across the Three Ecological Zones

The values recorded for the ash concentrations of the bamboo culms or stems range from 0.93 to 2.11%. The results obtained were similar to that reported by previous researchers. For example, Ota (1976) reported that bamboo ash ranged from 1.7 to 5.0%. Scurlock et al. (2000) also reported considerable variation of less than 1% for three Phyllostachys of bamboo investigated. The shoots were within the range of 1.91% to 4.99% of five other bamboo species reported by Dannenmann et al. (2007). Ratner (2011) studied the proximate analysis of wood chips and compared it with that of coal. The wood ash was 2.24 wt %, while coal was 10.6 wt %. Ash content from switchgrass (dry basis) ranged from 4.4 wt % to 9.2 wt % (Benson and Laumb 2010).

Carbon Concentrations in Bambusa vulgaris

The mean percentage of carbon concentrations in mature culm varied from 48.46 to 53.31%. The findings fell within the range of 48.5% to 50% on a dry basis for bamboo (Choy et al. 2005), 45 to 55% (Ganesh 2003, Vessia 2006), and carbon contents in three bamboos based on their age (1 year to 5 years) ranged from 51.39 to 51.84 (Scurlock et al. 1999). Higher carbon content leads to a higher high heating value (Clarke and Preto 2011).

Hydrogen Concentrations in Bambusa vulgaris

The mean percentages of hydrogen recorded in the bamboo culms of the age groups were between 5.60 and 6.56%. These were similar to other researchers who reported that the hydrogen content of bamboo culms varies from 4.8 to 6.7% (Ganesh 2003), 6% (Jenkins 1998) and 6.0 to 6.5% (Choy et al. 2005). However, Scurlock et al. (1999) recorded the hydrogen content in three bamboos based on their age as 1 year (4.90 to 5.21%), 2 years (5.00 to 5.29%), and 4 to 5 years (4.51 to 5.40%). Higher hydrogen content leads to a higher high heating value (Clarke and Preto 2011). Hydrogen is a reducing gas and the cracking of biomass in the presence of hydrogen can reduce the oxygen content for example in bio-oil (Zhou et al. 2013).

Nitrogen Concentrations in Bambusa vulgaris Across the Three Ecological Zones

Nitrogen also had a mean percentage weight between 0.32 and 2.52%. The percentage of 2.52% was recorded in the shoot. The shoot is not recommended for fuel production because its values were above the threshold set by the European standard EN 15104 (2011) according to which nitrogen should be above 1% in biomass for fuel production. Apart from the shoot, the other samples were similar to the earlier studies; from 0.2% to more than 1% (Jenkins et al. 1998); 0.4 to 1.3% (Ganesh 2003), and 0.3% (Choy et al. 2005). The results of experiments by Scurlock et al. (1999) show that the nitrogen contents in three bamboos based on their age were 1 year (0.4 to 0.59%), 2 years (0.29 to 0.6%), and 4 to 5 years (0.21 to 0.38%). Oxides of nitrogen (NOx) cause ozone, smog, and respiratory problems. Wood and fuel oil combustion have similar levels of NOx emissions (Maker 2004). Nitrogen in fuel feedstock is responsible for most nitrogen oxide (NOx) emissions produced from biomass combustion. Lower nitrogen content in the fuel should lead to lower NOx emissions (Clarke and Preto 2011).

The Relationships Between the Physical and Fuel Properties of the Bamboo (Bambusa vulgaris)

The Relationship Between Wet and Dry Moisture Content

The relationship between wet moisture content and dry moisture content has a strong positive correlation, r=0.609; p>0.05. The moisture content of fresh bamboo increases the weight of the bamboo. The wetter the bamboo the heavier it will be. Wet wood or bamboo produces more smoke (volatile matters), which is ineffective.

The Relationship Between Moisture Content and High Heating Values

There was a positive relationship between moisture content in dried bamboo and the high heating value (r=0.059 and p>0.05). Moisture content in wet bamboo relates negatively with high heating value (r=-0.188 and p>0.05). This means that dried bamboo produces more heat than wet bamboo. The study shows that the high heating value in the bamboo samples decreases with high moisture content. High moisture content reduces the heat in the bamboo and reduces boiler efficiency (Lyngfelt et al. 2001).

The Relationships Between Moisture Content and Ash Content of The Bamboo

There were variations between moisture contents (wet and dry bases of the bamboo) and ash content. There was a negative correlation between the moisture content of wet bamboo and the ash content (r=-0.064 and p>0.05), whilst the dry bamboo relates positively with ash content (r=0.330 and p>0.05). These imply that more moisture in the bamboo produces less ash content. It is most likely that the minerals in the bamboo are evaporated in the form of smoke and steam.

The Relationships Between Moisture Content and Density of the Bamboo

There was a positive correlation between the moisture content of wet or fresh bamboo and basic density (r=0.145 and p>0.05). This shows that fresh bamboo is heavier than the similar dried type.

The Relationship Between High Heating Value and Hydrogen and Carbon Contents

The correlation between the high heating value and hydrogen was very strong and positive (r=0.755). A high percentage of hydrogen in the bamboo gives high heating values. This points out that higher hydrogen content is desired in bamboos to increase the high heating values. The relationship between high heating value and carbon was significant (r=0.724 and p=0.05). Carbon is one of the main components of biomass, which increases the high heating value. Therefore, high carbon content is needed in biofuels.

The Relationship Between High Heating Value and Ash Content

There was an intermediate negative correlation between the high heating value and the ash content (r=-0.603 and p>0.05). The bamboo sample which has less ash content produces more heat than bamboo with high ash content. There was a negative correlation between carbon content and the ash content (r=-0.872 and p>0.05). The higher the percentage of carbon contents in the fuel, the lower the ash content. In biofuel production lower ash content is required, so that ash content will not produce slag, foul, and also corrode the conversion plant.

CONCLUSION

The moisture content of fresh bamboo increases the weight of the bamboo. High moisture content reduces the heat value in the bamboo and reduces boiler efficiency. Therefore, fresh bamboos produce more smoke (volatile matters), which may be injurious to human health. Carbon, hydrogen, and oxygen are the main components of biomass that increase the high heating value. Therefore, high carbon, hydrogen, oxygen, and lower ash content recorded in the study predict its suitability as a biofuel material. Fuel properties of Bambusa vulgaris are comparable to some wood types, lower to denser wood types, but higher than most of the herbaceous energy crops and agricultural residues. This means that Bambusa vulgaris may be a good feedstock for the production of bioenergy in terms of heat, charcoal, biogas, bio-power, and transportation fuel.

Author Contributions

KA, GA, S A, JA-Y conceived and designed the research, carried out the field and laboratory measurements and processed the data, drafted the manuscript, and wrote the manuscript.

Funding

This research received no external funding.

Acknowledgment

The authors are very grateful to Dr. Joseph Acquah at the Department of Agriculture (soil and chemistry lab) at the Kwame Nkrumah University of Science and Technology, Kumasi – Ghana.

REFERENCES

Agarwal AK, 2007. Biofuels (alcohols and biodiesel) applications as fuel for internal combustion engines. Prog Energ Combust 33(3): 233-271. https://doi.org/10.1016/j.pecs.2006.08.003.

Amoah M, Cremer T, 2017. Net calorific values and mineral concentration of thirteen tree and shrub species in Ghana. J Sustain Forest 36(7): 703-716. https://doi.org/10.1080/10549811.2017.1351375.

ASTM E873-82. 2013. Standard Test Method for Bulk Density of Densified Particulate Biomass Fuels. ASTM International, West Conshohocken, PA, USA. Available online: https://www.astm.org/e0873-82r19.html (28 May 2021).

ASTM International, 2008 ASTM D 1102-84, Test Method for Ash in Wood. Annual Book of ASTM Standards, pp. 153-154.

Bain RL, 2010. Hydrogen Production from Biomass. NREL US Department of Energy.

Benson S, Laumb M, 2010. Analysis Report: Chemical and Heat Value Characterization of Perennial Herbaceous Biomass Mixtures. Mirobeam Technologies Inc.

Bridgwater AV, 2004. Biomass Fast Pyrolysis. Therm Sci 8(2): 21-49. https://doi.org/10.2298/TSCI0402021B.

Brown RC, 2003. Biorenewable Resources: Engineering New Products from Agriculture. Wiley-Blackwell, 388 p.

Choy KKH, Barford JP, McKay G, 2005. Production of Activated Carbon from Bamboo Scaffolding Waste Process Design, Evaluation, and Sensitivity Analysis. Chem Eng J 109(1-3): 147-165. https://doi.org/10.1016/j.cej.2005.02.030.

Clarke S, Preto F, 2011. Biomass Densification for Energy Production. Ontario Ministry of Agriculture, Food and Rural Affairs, ON, Canada.

Dannenmann BME, Choocharoen C, Spreer W, Nagle M, Leis H, Neef A, Mueller J, 2007. The Potential of Bamboo as a Source of Renewable Energy in Northern Laos. In: Conference on International Agricultural Research for Development, Göttingen, Germany, 9-11 October 2007. Tropentag University of Kassel-Witzenhausen and University of Göttingen, p. 5.

Davis SJ, Caldeira K, 2010. Consumption-based accounting of CO2 emissions. PNAS 107(12): 5687-5692. https://doi.org/10.1073/pnas.0906974107.

Demirbas A, Arin G, 2002. An Overview of Biomass Pyrolysis. Energ Source 24 (5): 471-482. https://doi.org/10.1080/00908310252889979.

Demirbas A, 2010. Fuels from Biomass. In: Biorefineries. Green Energy and Technology. Springer, London, UK, pp. 33-73. https://doi.org/10.1007/978-1-84882-721-9_2.

Doggart N, Meshack C, 2017. The Marginalization of Sustainable Charcoal Production in the Policies of a modernizing African nation. Frontiers in Environmental Science 5: 27. https://doi.org/10.3389/fenvs.2017.00027.

Duku MH, Gu S, Hagan EB, 2011. A Comprehensive Review of Biomass and Biofuels Potential in Ghana. Renew Sust Energ Rev 15(1): 404-415. https://doi.org/10.1016/j.rser.2010.09.033.

Ebanyenle E, Oteng-Amoako AA, 2007. Site Differences in Morphological and Physical Properties of Bambusa vulgaris Grown in Ghana. Discov Innovat 19(3): 222-225.

European Standard (EN 15104), 2011. Solid biofuels-Determination of Ash content of all solid biofuels.

FAO, 2005. Ghana Aqua stat 2005. In: AQUASTAT - FAO's Global Information System on Water and Agriculture. Food and Agricultural Organisation of the United Nations. Available online: https://www.fao.org/aquastat/en/countries-and-basins/country-profiles/country/GHA (5 April 2021).

Filho AP, Badr O, 2004. Biomass Resources for Energy in North-Eastern Brazil. Appl Energ 77(1): 51-57. https://doi.org/10.1016/S0306-2619(03)00095-3.

Ganesh A, 2003. Bamboo Characterization for Thermochemical Conversion and Feasibility Study of Bamboo Based Gasification and Charcoal Making. Energy Systems Engineering of Indian Institute of Technology, Mumbai, India.

Hall JB, Swaine MD, 1981. Distribution and Ecology of Vascular Plants in A Tropical Rain Forest. Springer, Dordrecht, The Netherlands, 383 p. https://doi.org/10.1007/978-94-009-8650-3.

IEA, 2010. Carbon Capture and Storage: Progress and Next Steps. In: IEA/Carbon Sequestration Leadership Forum (CSLF) report to the Muskoka 2010 G8 Summit.

IEA, 2011. Technology Roadmap, Biofuels for Transport. International Energy Agency, Paris, France.

IEA, 2008. 2008. Key World Energy Statistics. OECD/IEA (International Energy Agency), Paris, France.

INBAR, BARADEP, 2003. International Network for Bamboo and Rattan (INBAR) and Bamboo and Rattan Development Program (BARADEP). In: Proceedings of Bamboo housing workshop, 31 March - 4 April 2003, WITC, Kumasi, Ghana.

ISO 3131, 1975. Wood-Determination of Density for Physical and Mechanical Tests.

Jenkins BM, Baxter LL, Miles Jr TR, 1998. Combustion Properties of Biomass. Fuel Process Technol 54(1-3): 17-46. https://doi.org/10.1016/S0378-3820(97)00059-3.

Koh LP, Wilcove DS, 2008. Is Oil Palm Agriculture Destroying Tropical Biodiversity? Conserv Lett 1(2): 60-64. https://doi.org/10.1111/j.1755-263X.2008.00011.x.

Koutsoyiannis D, Makropoulos C, Langousis A, Baki S, Efstratiadis A, Christofides A, Karavokiros G, Mamassis N, 2009. 1HESS Opinions: "Climate, Hydrology, Energy, Water: Recognizing Uncertainty and Seeking Sustainability". Hydrol Earth Syst Sci 13(2): 247-257. https://doi.org/10.5194/hess-13-247-2009.

Lyngfelt A, Leckner B, Mattisson T, 2001. A fluidized-bed combustion process with inherent CO2 separation; application of chemical-looping combustion. Chem Eng Sci 56(10): 3101-3113. https://doi.org/10.1016/S0009-2509(01)00007-0.

Maker TM, 2004. Wood-chip High heating Systems.

Mclean EO, 1965. Aluminum in Methods of Soil Analysis. America Science Agronomy, Madison, Wisconsin, USA, pp. 978-998.

Montano CD, 2014. Torrefied Bamboo: An Alternative for Sustainable Biomass Export. Sustainable Biomass Production in Latin America, Bogota, Columbia.

Motsara MR, Roy NR, 2008. Guide to Laboratory Establishment for Plant Nutrient Analysis. 19th Edition, FAO, Rome, Italy, pp. 42-88.

Nelson DW, Sommers LE, 1982. Total Carbon, Organic Carbon, and Organic Matter. In: Page AL, Miller RH, Keeney D (eds) Methods of Soil Analysis. American Society of Agronomy, Madison, USA, pp. 539-594.

Obiri BD, Oteng-Amoako AA. 2007. Sustainable Development of the Bamboo Industry in Ghana. Ghana Journal of Forestry 21-22: 14-27.

Ota M, 1976. Studies on the constituents of leaves of Bamboo grass, sasa spp (sect. Sasa) Isolation of Hemicelluloses and Preparation of Carboxy-methyl Hemicellulose. The College Forest, Hokkaido University, Sapporo, Japan.

Oteng-Amoako AA, Ofori D, Anglaare LCN, Obiri BD, Ebanyenle E, 2005. Sustainable Development of Bamboo Resources of Ghana and Togo. Progress Report Submitted to Africa Forest Research Network, Nairobi, Kenya.

Preto F, 2010. Review of Biomass Conversion Technologies. Canmet ENERGY, Natural Resources Canada BIOENERGY: Solutions for Community Sustainability Prince George.

Prins MJ, 2005. Thermodynamic Analysis of Biomass Gasification and Torrefaction. Technische Universiteit Eindhoven, Eindhoven, The Netherlands. https://doi.org/10.6100/IR583729.

Qisheng ZJ, Shenxue Tongyu T, 2002. Industrial Utilization of Bamboo. INBAR Technical Report No. 26 Section 1, pp. 3-4.

Ratner A, 2011. CFD Modeling of Co‐Firing Wood Chips with Coal for UI Power Plant Boiler 10. Partial Final Report to Utilities Group University of Iowa, USA.

Riché B, Hachileka E, Awuor CB, Hammill A, 2009. Climate-Related Vulnerability and Adaptive-Capacity in Ethiopia’s Borana and Somali Communities. International Institute for Suistanable Development (IISD). Available online: https://www.iisd.org/publications/report/climate-related-vulnerability-and-adaptive-capacity-ethiopias-borana-and-somali (10 March 2021).

Sathre R, O’Connor J, 2010. A Synthesis of Research on Wood Products and Greenhouse Gas Impacts 2nd Edition. Technical Report No.TR-19R FP Innovations.

Scurlock J, 1999. Oak Ridge National Laboratory. Bioenergy Feedstock Development Programs, P.O. Box 2008, Oak Ridge.

Scurlock JMO, Dayton DC, Hames B, 2000. Bamboo, an Overlooked Biomass? Report by Oak Ridge National Laboratory, Oak Ridge, Tennessee (USA). Environmental Sciences Division Publication No. 4963.

Street J, Yu F, 2011. Production of High-Value Products Including Gasoline Hydrocarbons from Thermochemical Conversion of Syngas. Biofuels 2(6): 677-691. https://doi.org/10.4155/bfs.11.141.

Sun Y, Cheng J, 2002. Hydrolysis of Lignocellulosic Materials for Ethanol Production: a review. Bioresource Technol 83(1): 1-11. https://doi.org/10.1016/S0960-8524(01)00212-7.

Technical Support Document, 2007. Methodology for Thermal Efficiency and Energy Input Calculations and Analysis of Biomass Cogeneration Unit Characteristics. Available online: https://www3.epa.gov/airtoxics/utility/fnl_biomass_cogen_TSD_04_19_07.pdf (10 March 2021).

Tekpetey SL, 2011. Bamboo Resources in Ghana: Diversity, Properties, Products, and Opportunities. International Tropical Timber Organizations.

Templeton DW, Scarlata CJ, Sluiter J, Wolfrum E, 2009. Biomass Compositional Analysis Method Variability. Poster presented at 31st Symposium on Biotechnology for Fuels and Chemicals, 3-6 May 2009, San Francisco, CA, USA. Available online: https://www.nrel.gov/docs/fy09osti/45799.pdf (10 May 2021).

The NEED Project, 2011. Biomass at a Glance Manassas, Virginia, USA. Available online: www.NEED.org (20 May 2021).

TSI Incorporated, 2004. An Overview of Measurements, Methods, and Calculations Used in Combustion Analysis. P/N 2980175 Rev. B U.S.A. Combustion Analysis Basics.

Vessia AV, 2006. Cellulosic Biomass: Properties and Characteristics. Zero Emissions Resource Organisation (ZERO), Maridalsveien, Oslo, Norway.

White EM, 2010. Woody Biomass for Bioenergy and Biofuels in the United States— A Briefing Paper. Gen. Tech. Rep. PNW-GTR-825. Portland, OR: U.S. Department of Agriculture, Forest Service, Pacific Northwest Research Station, 45 p. https://doi.org/10.2737/PNW-GTR-825.

WHO, 2016. Burning Opportunity: Clean Household Energy for Health, Sustainable Development and Wellbeing of Women and Children. World Health Organization, Geneva, Switzerland, 113 p. Available online: https://apps.who.int/iris/handle/10665/204717 (20 May 2021).

World Bank, 2009. Ghana Economics of Adaptation to Climate Change. Consultation Draft Sustainable Development Department, Africa Region.

Zhou L, Jia Y, Nguyen H, Adesina AA, Liu Z, 2013. Hydro pyrolysis Characteristic of Kinetics of Potassium – Impregnated Pine Wood. Fuel Process Technol 116: 149-157. https://doi.org/10.1016/j.fuproc.2013.05.005.

© 2022 by the Croatian Forest Research Institute. This is an Open Access paper distributed under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/4.0).